Technology for professionals

Our machines stand out thanks to their robust and long living construction, their practical functionality and their ability to consistently meet future requirements thanks to innovative developments. We see ourselves as a partner to our customers, ready to provide comprehensive advice- and service concept. Agricultural technology from Beyne directly contributes to our customers' personal success and professional enjoyment.

Rotary harrows for all cultivation processes

Seedbed preparation - an important success factor:

A homogenous seedbed is the crucial basic requirement for the uniform germination and early development of the whole crop. This is because in comparison to the natural factors in place such as the type of soil, light conditions and water supply, growth and plant development are clearly influenced by seed preparation. Seedbed preparation - an important success factor: Arterra M 302 with crumbling packer roller.

The requirements for optimum seed preparation are:

• An even distribution of the plant remains (influences light conditions and nutrient reservoir)

• No deep tramlines or compressed zones in the soil

• Uniform working depth, prevention of unnecessarily deep cultivation

• Ground structuring with fine soil in the sowing horizon and a rougher, crumbly structure on the surface

Beyne rotary harrows are consistently geared towards these practical requirements. The wide selection of different designs covers the range between conventional seedbed preparation after ploughing right through to powerful, combined mulch-sowing. The various equipment options allow the best possible solutions and in doing so create the basis for a successful crop.

Fields of application

The use of rotary harrows can be essentially divided into three method groups which differ in the nature and sequence of work steps. The choice depends on the local conditions and the respective cultivation strategy.

- Conventional seedbed preparation in the ploughing process

Solo

Conventional soil cultivation is characterised by the clear sequence of the three cultivation processes - ploughing, seedbed preparation and sowing. Under good conditions, ploughing works all plant remains deep into the ground and weeds are destroyed through the deprivation of light and air. The cultivation depth is usually between 15 - 30 cm. An appropriate reconsolidation and sufficiently fine crumbling for optimum germination conditions is then achieved with secondary soil cultivation.

- Conventional seedbed preparation in the ploughing process

Combined with sowing technology

Due to its design principle, a rotary harrow is ideally suited for combined use with sowing technology. Thanks to the compact design, an enormously high lifting power of the tractor hydraulics is not required even with a seed drill, the rear axle and hydraulics are protected and the tractor and equipment remain safe to drive. Both mechanical or pneumatic drills as well as precision seed drills are suitable for the combination. The greatest advantages of combining the use of seedbed preparation and sowing are clearly that time and energy is saved but also, of course, from the point of view of the arable farmer, that the soil is protected due to a reduction of the individual passes.

- Conservation cultivation in the mulch-sowing process

Combined with sowing technology

Of course, rotary harrow/seeder combinations are also suitable for mulch-sowing because the intensive mixing of the mulch material and very good crumbling create optimum germination conditions. The heavier the soil conditions, the more obvious these advantages become, meaning that less passes with the cultivator are necessary. In addition, fewer demands are also placed on the coulter system of the seed drill. Behind the rotary harrow, conventional drills generally perform smoothly even in mulch-sowing. The rotary cultivator is particularly suited for work in mulching conditions. The "at the ready" tines provide very good penetration and even allow work to be carried out in soils which have not been pre-cultivated.

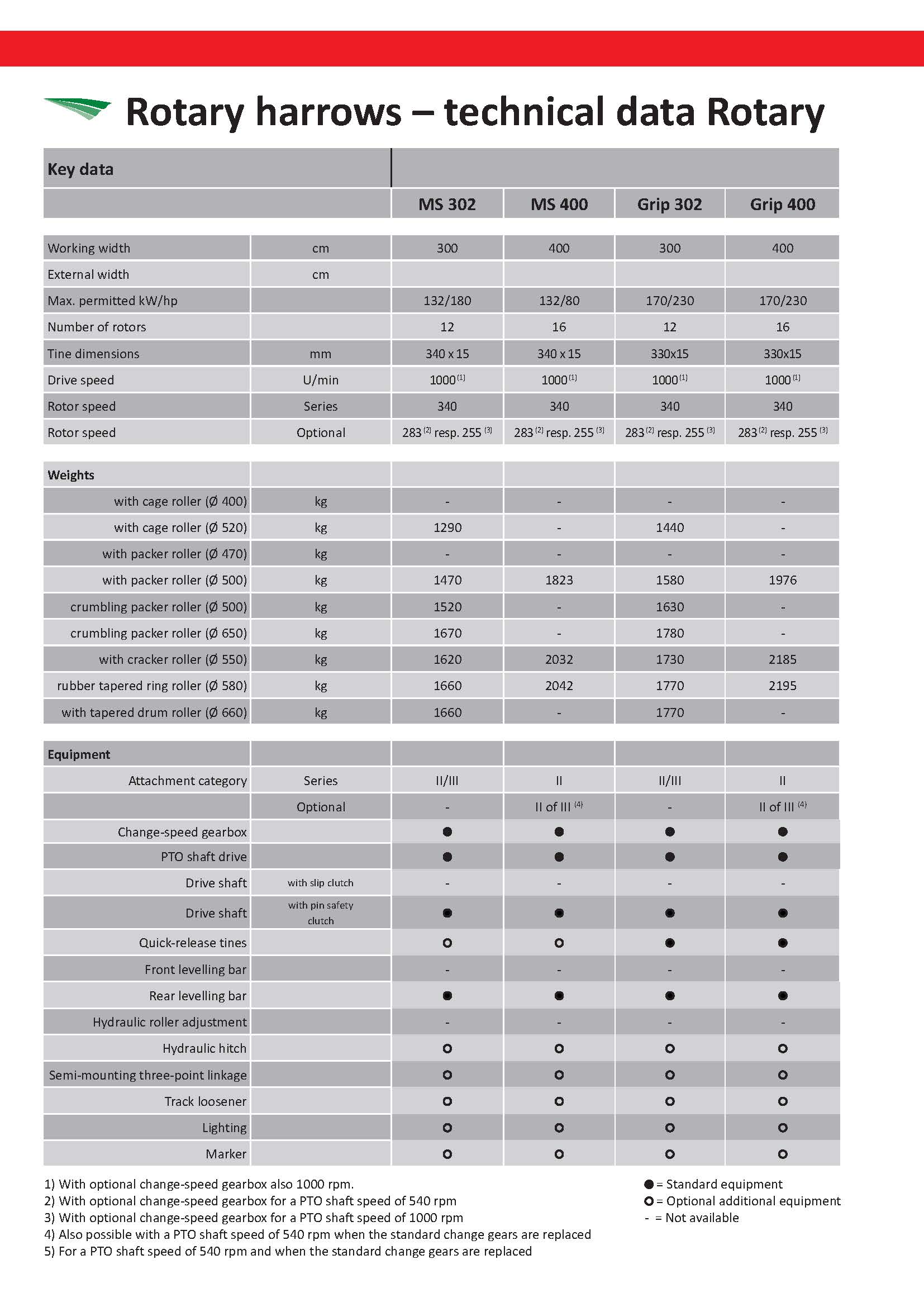

Change-speed gearbox

The gearbox is designed for very high tractor performances and stands out in the Arterra rotary harrow range due to the fact that it is extremely reliable. The PTO shaft stub is positioned centrally and right at the back. This ensures limited bending of the drive shaft and therefore smooth operation. Comes with PTO shaft drive as standard for combined use with seed drills. Can be used for a PTO shaft speed of both 540 and 1000 rpm. It is aligned simply by adjusting the change gears.

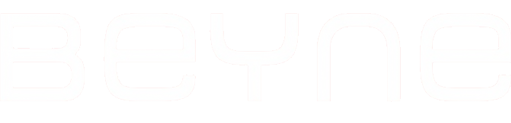

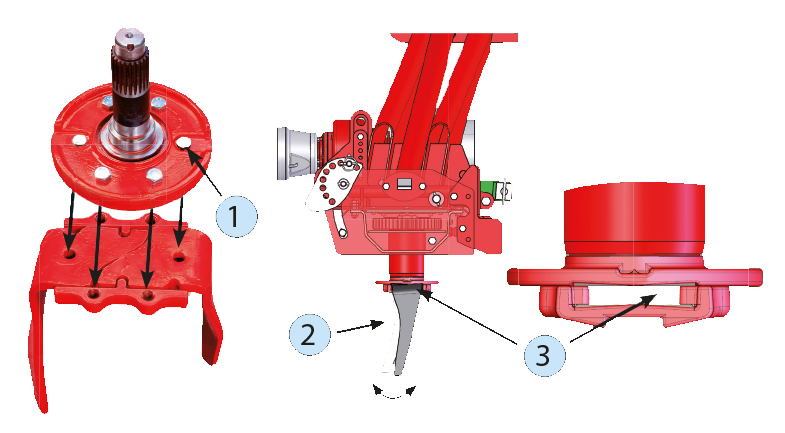

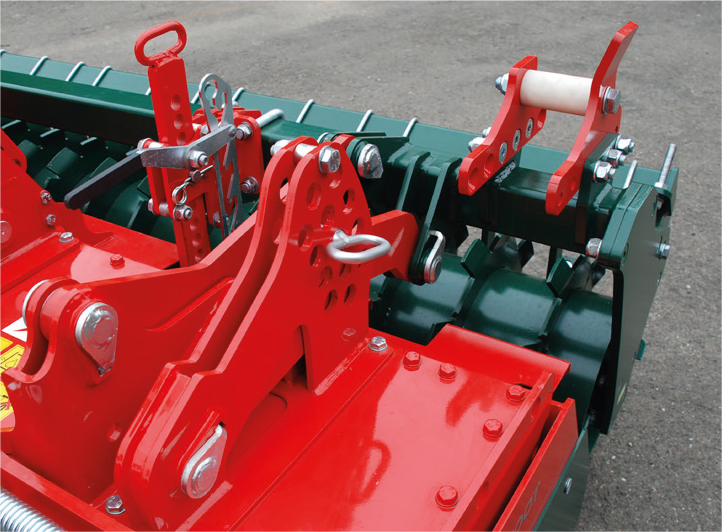

Tine quick changeover system

The Beyne tine quick changeover system is characterised by the fact that the fastening bolts (1) hardly have to take on any stresses during the work. Thanks to their special construction, the tines are positively kept in position in the ground and can be easily removed after the removal of the fastening bolts. The spring-loaded mounting (2) of the tines in the special slot in the holder (3) is an integrated stump-jump system and protects the components of the implement.

Rotors

The rotor shaft (Ø 50 mm) and tine bracket are forged from one part and are therefore particularly robust. An incredibly high-quality shaft seal guarantees long-term leak tightness and therefore the longevity of the Arterra rotary harrow: A labyrinth prevents the penetration of rough parts and therefore damage to the seal elements from the outside. Twin shaft sealing rings reliably keep the oil in the pan. The standard stone guard on the pan reliably prevents the stones from jamming between the rotors and, in doing so, contributes to the long service life of Arterra implements.

Tines

As standard, the Arterra MS is equipped with screwed-on knife tines made from microalloyed fine-grained boron steel of 340 mm in length. These provide an excellent service life. The quick tine changeover system is optionally available and can also be retrofitted. In this process, a specially forged counterplate is screwed onto the existing tine carrier which then holds the quick-fit tines (see below).

Pan design

Combined with the special pan design, the highly robust tapered roller bearing with a large bearing clearance and a material thickness from 6 mm provides a very high level of stability. The additional base of the pan is welded over the entire working width and therefore reinforces the pan and bearings. The drive wheels and the bearings are lubricated with oil. This guarantees an optimum lubricating effect, regardless of the surrounding temperatures.

Diamant tines

Strength meets strength with VN Diamant wearing parts

As a high-end solution for soils which increase wear/for work in hard soils or soils which have not been pre-cultivated, the Arterra MS knife tines and the grip tines of the ArterraGrip rotary cultivator are also available with a hard metal facing. Small hard metal plates are applied to the actual part in a unique production process. It is characterised by the high level of strength, even of the basic material. These diamant wearing parts therefore guarantee a significantly increased service life, reduced expenditure on replacing parts and an overall reduction in costs due to wear. Due to the dimensional stability of the tines, the working quality of the entire machine also remains consistently high throughout the entire lifecycle of the parts. This is particularly the case for the outstanding mixing effect of the grip tines.

Strenghts

Side plates

The stable side plates are double conducted, break-proof and light weight.

Depth adjustment

The placement of the depth adjustment at the Arterra machines takes place by a fine adjustment perforated plate with a coupling pin.

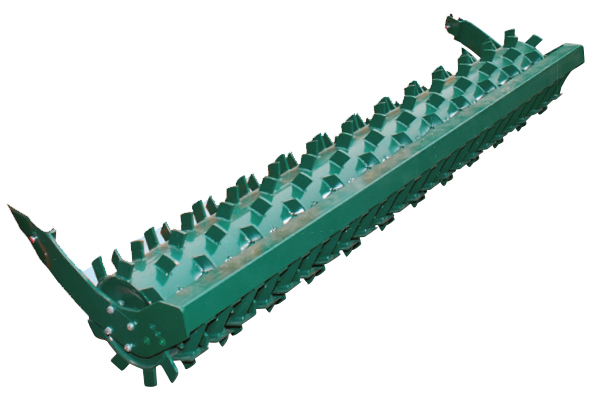

Levelling bar

Comfortable handling with the basic setting. Levelling bar rolled out – correction at working depth adjustment is not necessary, optimum crumbly structure, top quality levelling.

Accessoires

Track eradicators

All Beyne rotary harrows are equipped with adjustable track eradicators. This option loosens the wheel tracks behind the tractor wheels and avoids irregular soil compaction.

Track indicator

The Arterra rotary harrows can also be fitted with track indicators for use with the seed drill. These are operated

by a double-acting hydraulic system and fold vertically.

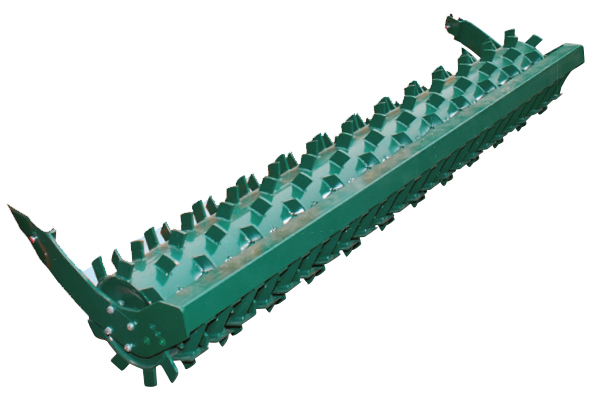

Rollers

Tubular cage roller:

400/480 or 520 mm diameter

- Good crumbling on average soils

- Leaves an open soil structure

- Lightweight

Packer roller:

470 or 500 mm diameter

- Very good all-round features

- Particularly clog-resistant, thanks to scraper

- Tough in stony conditions

- Good ground drive

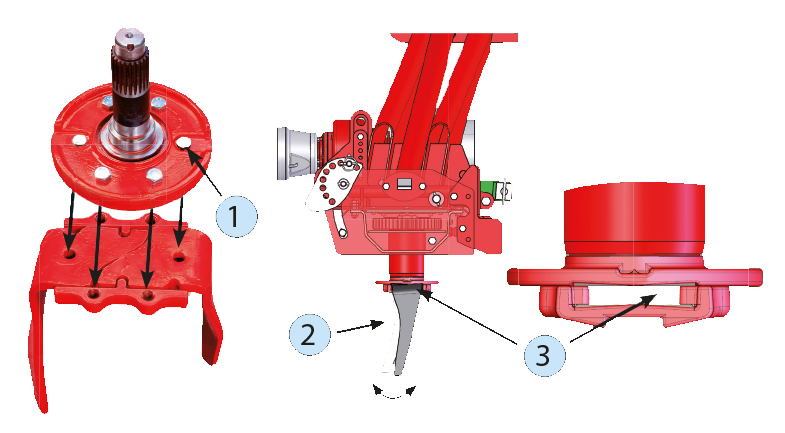

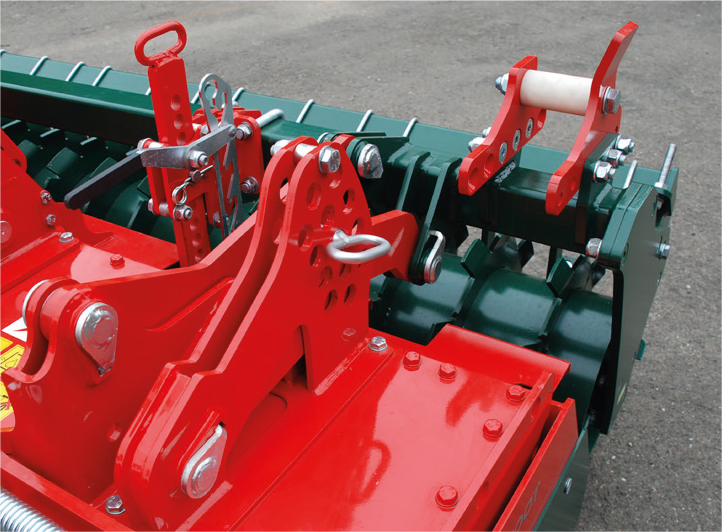

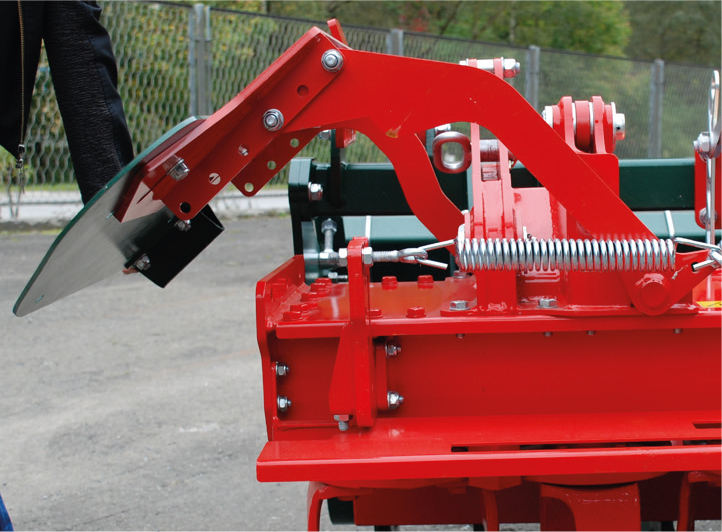

Seed drill mounting

Hydraulic hitch: A hydraulically operated hitch is available for combination with 3-point mounted seed drills. Robustly built, the lifting geometry shifts the weight of the seed drill forward to the optimum position and therefore reduces the entire lifting force requirement of the tractor. High lifting power through 2 cylinders (optional with stroke limitation).